High standards for our super-flat products

We are currently working on a large number of in-house projects. Whatever their stage of development, we always strive to add real therapeutic value. We measure the innovations in our new transdermal patches against actual improvements in patient quality of life. Ultimately, this patient-centric approach is also beneficial for our customers and partners. Our own product range includes robust formulations that are often shown to have better properties than the originals. In other words, you can leverage our innovative ability to maintain your competitive edge.

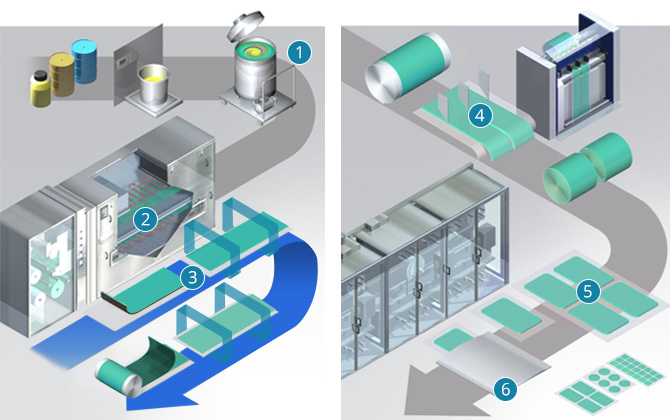

How our matrix patches are made

- All materials are mixed and weighed to create an adhesive mass containing the active substance

- Coating of the adhesive mass

- Drying and lamination

- The laminate is cut into smaller rolls

- The patches are die-cut

- The individual patches are sealed in pouches (primary packaging)